Tym Tractor Problems: Troubleshooting Tips & Solutions

Are you having issues with your Tym tractor problems lately and don’t seem to get the hang of it? Don’t worry; I have you covered.

Tym tractors are well-known for their excellent performance and stability, but like any machinery, they can experience certain problems.

As reported by users, the most commonly reported problems with Tym tractors include engine performance issues, hydraulic system malfunctions, electrical system failures, and transmission problems, which can impact their overall functionality and performance.

In this article, I’ll walk you through these problems, explaining how you might’ve gotten them in the first place and how to counter them. Let’s get started.

4 Common Tym Tractor Problems

1. Engine Performance Issues

Tym Tractors are renowned for having strong engines, but like any machinery, they sometimes experience problems performing.

To ensure the best performance, you must address any engine-related issues immediately.

Here are some common engine performance issues and their potential solutions:

1. Lack of Power

Causes

Clogged fuel filters, dirty air filters, fuel quality issues, or worn-out engine components.

Solution

Replace or clean fuel and air filters regularly, use high-quality fuel, and inspect engine components for wear and tear.

2. Rough Acceleration

Causes

Incorrect fuel-to-air ratio, dirty fuel injectors, spark plug issues, or vacuum leaks.

Solution

Check and adjust the fuel-to-air ratio, clean or replace fuel injectors, inspect and replace spark plugs if necessary, and inspect vacuum lines for leaks. If the problem persists, seek professional assistance.

Rural King Tractors Are Junk or Good? [Good & Bad Side] 2023

3. Engine is Unresponsive

Causes

Broken ignition coils, damaged spark plugs, or fuel delivery problems.

Solution

Test and replace faulty ignition coils, inspect and replace worn-out spark plugs, and ensure proper fuel delivery by checking the fuel pump and injectors.

4. Excessive Smoke

Causes

Incorrect fuel mixture, worn-out piston rings, or valve seal issues.

Solution

Adjust the fuel mixture, inspect and replace worn-out piston rings, and check and replace faulty valve seals if needed. Seek professional help if necessary.

5. Engine Stalling

Causes

Clogged fuel lines, malfunctioning sensors, or electrical system issues.

Solution

Check and replace malfunctioning sensors, and clean or replace clogged fuel lines. Also, check the electrical system for any loose connections or broken parts.

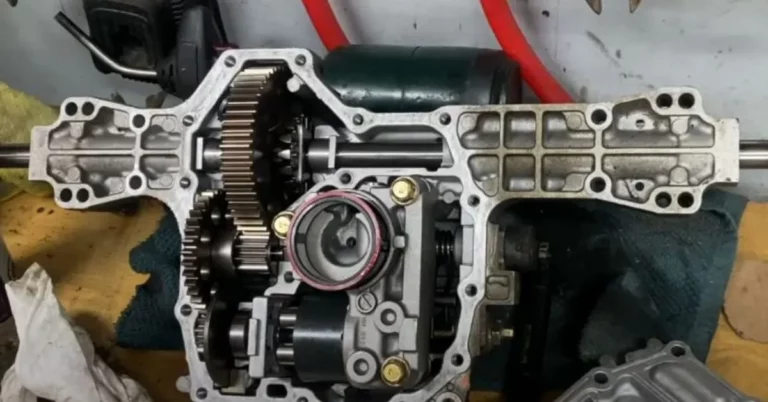

2. Hydraulic System Malfunctions

The hydraulic system in Tym Tractors is responsible for powering various attachments and implements.

You might experience the following typical hydraulic system issues. Here are possible causes and fixes:

1. Slow or Weak Attachment Movement

Causes

Low hydraulic fluid level, clogged filters, or a worn-out hydraulic pump.

Solution

Check and maintain the proper hydraulic fluid level, clean or replace clogged filters, and inspect the hydraulic pump for any signs of wear. If needed, replace the pump with a new one.

2. Erratic Attachment Operation

Causes

Air trapped in the hydraulic system, a faulty control valve, or damaged hydraulic hoses.

Solution

Check the hydraulic system to remove air pockets, test and replace the faulty control valve if necessary, and inspect the hydraulic hoses for leaks or damage. Repair or replace damaged hoses promptly.

3. Hydraulic Leaks

Causes

Damaged or worn-out hydraulic seals, loose connections, or cracked hydraulic lines.

Solution

Inspect all hydraulic seals and replace any that are damaged. Ensure all connections are tightened, and fix or replace cracked hydraulic lines. Regularly check for and address any hydraulic leaks to prevent further damage.

Also Read: John Deere 100 Series Transmission Problems – Fixed!

4. Unresponsive Hydraulic Controls

Causes

Faulty control lever or joystick, electrical connection issues, or hydraulic valve problems.

Solution

Test and replace the faulty control lever or joystick if needed. Check and secure all electrical connections related to the hydraulic system. Inspect and troubleshoot hydraulic valves to ensure proper functioning.

5. Overheating of Hydraulic Fluid

Causes

Insufficient cooling, a blocked hydraulic oil cooler, or an excessive load on the hydraulic system.

Solution

Ensure proper cooling by cleaning or replacing the hydraulic oil cooler if blocked. Avoid overloading the hydraulic system and operating within the recommended limits to prevent overheating. Monitor hydraulic fluid temperatures regularly.

3. Electrical System Failures

The electrical system in Tym tractors plays a crucial role in powering various components and ensuring smooth operation.

A malfunction in the electrical system can have serious consequences.

Here are some common electrical system problems and their potential solutions:

1. Battery Drainage

Causes

Either there is faulty wiring, a malfunctioning alternator, or the accessories are left on when you are not using the tractor.

Solution

Check the wiring for any damage or faulty connections, and make any necessary repairs.

Test the alternator’s output to ensure it is charging the battery properly. Turn off all accessories when the tractor is not used to prevent battery drainage.

2. Inoperative Lights or Meters

Causes

Burnt-out bulbs, loose connections, or a faulty switch.

Solution

Check and replace any burned-out bulbs in the lights or gauges. Inspect and secure all electrical connections to ensure they are properly attached. Test and replace any faulty switches that control the lights or gauges.

3. Blown Fuses

Causes

Electrical overloads, short circuits, or faulty components.

Solution

Identify the cause of the electrical overload or short circuit and address it. Replace blown fuses with new ones of the right rating.

4. Transmission Problems

The tractor’s transmission systems are essential for the engine to control speed and direction.

Here are some common transmission issues and some potential fixes:

1. Difficulty Shifting Gears

Causes

A worn-out clutch, low transmission fluid, or a malfunctioning gear shift system.

Solution

Ensure the transmission fluid is at the proper level and quality, and top it off or replace it as needed. Inspect and replace a worn-out clutch. Test and repair or replace any faulty components of the gear shift mechanism.

2. Slipping or Inconsistent Clutch Engagement

Causes

Worn-out clutch plates, improper clutch adjustment, or a faulty clutch release mechanism.

Solution

Inspect the clutch plates for wear and replace them if needed. Test and repair or replace any faulty components of the clutch release mechanism.

3. Loss of Power or Stalling

Causes

Clogged or dirty fuel filters, inadequate fuel supply, or a malfunctioning transmission control module.

Solution

Clean or replace clogged fuel filters. Ensure an adequate fuel supply by checking the fuel tank and lines. Test and diagnose the transmission control module for any issues and repair or replace it as necessary.

4. Noisy or Vibrating Transmission

Causes

Insufficient or contaminated transmission fluid, worn-out bearings, or misaligned components.

Solution

Check the quality and level of the transmission fluid, and if necessary, top it off or replace it. Inspect and replace worn-out bearings. Realign any misaligned components to reduce noise and vibrations.

Routine Maintenance Tips

Maintaining a regular maintenance schedule will keep your Tym tractor in top shape and eliminate any potential problems.

Here are some essential maintenance tips to help you ensure the performance and long life of your tractor:

1. Regular Fluid Checks

Regularly check the engine oil, coolant, hydraulic fluid, and transmission fluid levels. Top off or replace the fluids while adhering to the manufacturer’s recommendations.

2. Filter Maintenance

Clean or replace air, fuel, and hydraulic filters at the recommended intervals. Clogged filters can affect the performance of various systems and decrease fuel efficiency.

3. Lubrication

Properly lubricate all moving parts and components, including the chassis, joints, and pivot points. Use the suggested lubricants, and stick to the manufacturer’s recommendations for lubrication intervals.

4. Battery Care

Inspect the battery regularly for corrosion and ensure proper cable connections. Clean the terminals if necessary, and keep the battery charged to avoid starting issues.

5. Tire Inspection

Check tire pressure regularly. Inflate tires to the recommended pressure and replace them if the rubber is worn out.

6. Belt Inspection

Look for wear, cracks, or leaks in the drive belts. Replace them promptly to prevent system failures.

7. Cooling System Maintenance

Make sure the cooling fan is operating properly. Also, clean the radiator fins regularly. Check coolant levels and refill or replace coolant as needed.

Frequently Asked Questions (FAQs)

How often should I check the hydraulic fluid level?

It is recommended to regularly check the hydraulic fluid level, particularly before each use or at least once per week.

This ensures the hydraulic system is properly lubricated and helps prevent slow or weak attachment movement.

How can I prevent my Tym tractor from overheating?

To prevent overheating, ensure the radiator fins are clean and debris-free and that the cooling fan is functioning properly.

Moreover, avoid overloading the hydraulic system and operate the tractor within the recommended limits to prevent excessive heat buildup.

Is it necessary to use specific lubricants for my Tym tractor?

Yes, you must use the lubricants that the company recommends. Different components require different lubricants for their performance and to prevent wear.

You should refer to the operator’s manual or consult a trusted dealer to get the right lubricants for your tractor.

Conclusion

Addressing and resolving common problems with Tym tractors is important for maintaining the best performance and longevity.

You can ensure reliable operation and maximize your tractor’s lifespan by promptly addressing issues and performing routine maintenance.