Exmark Kohler Engine Oil Leaking Blown Head Gasket

Exmark is a reputable company that manufactures lawnmowers for both residential and commercial use.

These lawnmowers are well-known for their reliability, durability, and outstanding performance.

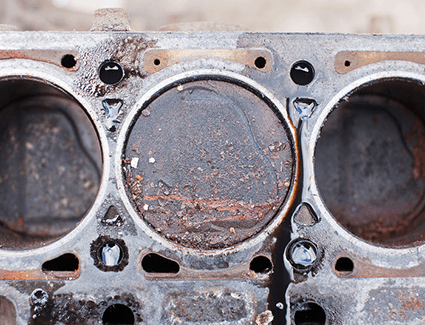

One of the most commonly reported issues Exmark lawnmower owners face using Kohler engines is oil leakage caused by a blown head gasket.

When the head gasket is blown, oil can leak out of the engine, leading to a decrease in performance and potential damage to the engine if left unattended.

This article will go through all the causes and symptoms of a blown head gasket in an Exmark lawn mower with a Kohler engine.

Additionally, I’ll offer some useful tips on fixing this issue and ensuring your lawn mower runs smoothly.

5 Reasons for a Blown Head Gasket

There are several reasons why the Exmark Kohler engine’s head gasket can fail. Here is a list of the most commonly reported reasons:

1. Overheating

Overheating is a common cause of head gasket failure. A hot engine can cause the cylinder head and engine to expand at different rates, which can cause the head gasket to crack.

This may lead to mixing coolant and oil, which could seriously harm the engine.

Overheating can be due to several factors, such as a faulty thermostat, a blocked radiator, a coolant leak, or a malfunctioning water pump.

Also Read: 5 Symptoms Of A Blown Head Gasket On A Kohler Engine

2. No Proper Maintenace

Poor maintenance can also lead to head gasket malfunction.

Failure to conduct routine maintenance, such as oil changes and coolant flushes, can make the gasket wear out over time, causing corrosion and erosion.

3. Old Gasket

Age can also be a contributing factor in head gasket failure.

Over time, the head gasket can wear out and fail, especially if it has been exposed to high heat or pressure.

This is more common in engines running for a long time or used for intensive purposes.

4. Improper Installation

Improper installation while assembling the engine can also lead to head gasket failure.

If the gasket is not installed correctly, it may not be able to cover the cylinder head and engine block completely as required.

This can lead to leaks of oil and coolant, which can cause engine damage over time.

5. Engine Modifications

Engine modifications can also result in head gasket failure. High-performance upgrades can add stress to the gasket, causing permanent failure.

This is especially true for engines modified for racing or high-stress applications.

Also Read: Ignition Coil Resistance Chart: Here’s How To Test

Symptoms of a Blown Head Gasket

A blown-up head gasket can show several defects in the lawnmower, along with oil leakage.

Here are the most commonly reported issues that are related to a blown head gasket:

1. Coolant leakage

Coolant, also known as antifreeze, is a liquid used to maintain an engine’s temperature.

In addition to oil leakage, a blown head gasket can also result in coolant leakage, leading to overheating and engine damage if left unchecked.

If you experience even a slight amount of leakage in the coolant, it is an alarming sign, and along with many other possible causes, a blown head gasket could be one of them.

2. Loss of power

Leaking oil or coolant caused by a blown head gasket can obviously cause engine power loss.

This is because the lawnmower could not function correctly when the engine oil was leaking.

Also Read: Ferris vs Exmark Lawn Mowers

3. Poor engine performance

Along with a loss of power, a blown head gasket can cause poor engine performance, including rough engine starts, misfires, and reduced acceleration.

If you observe any of these faults or symptoms in your Exmark Kohler engine, it is important to take steps to prevent further engine damage.

How to Fix a Blown Head Gasket in an Exmark Kohler Engine – Step-by-Step Guide

If you notice odd behavior or if you know the gasket has become faulty, take the following actions to have it replaced:

Step 1: Diagnosis of the Problem

Before attempting to make any repairs, identifying the cause of the problem is important.

I recommend hiring a professional mechanic who uses specialized tools to determine if the head gasket is the problem.

Step 2: Empty the Engine

Empty the lawnmower of any engine oil and coolants. Leaving this step out of the process can lead to serious accidents.

Step 3: Remove Cylinder Head:

Removing the cylinder head from the machine is required to access the head gasket.

This is a complex process that a professional mechanic should handle.

Step 4: Inspect Components

After removing the cylinder head, inspect the head gasket and other engine components for damage or wear. Replace any worn or damaged parts.

Step 5: Install a New Head Gasket

Install a new head gasket after ensuring that all necessary components have been replaced.

Step 6: Reassemble the Engine

Reassemble the engine as it was, ensuring all nuts and bolts are tightened according to the manufacturer’s instructions.

Step 7: Refill Fluids

After the engine has been reassembled, refill it with fresh oil and coolant.

Please Remember: Fixing a blown head gasket can be challenging, and it is best to leave it to professional mechanics.

Repairing the head gasket is always an option, but that would only ensure a short-term solution.

How You Can Prevent the Blowing Up of the Head Gasket – Tips

You can take several steps to reduce the chances of getting your lawnmower’s head gasket wrecked in the future.

Here is a list that you might find helpful:

- Regularly check and change the oil: The oil in the engine should be checked and changed regularly according to the manufacturer’s recommendations. This will help prevent engine damage and ensure proper engine performance.

- Monitor coolant levels: Coolant levels should be checked regularly to ensure the engine is properly cooled. If coolant levels are low, it can cause the engine to overheat, potentially causing damage to engine components.

- Use high-quality fuel and oil: Using high-quality fuel and oil can help prevent engine damage and ensure proper engine performance.

- Inspect engine components: Regularly inspect engine components, such as belts and hoses, for signs of wear or damage. Replace any worn or damaged components as needed.

- Follow the manufacturer’s instructions: Follow the manufacturer’s recommended maintenance schedule for the engine. This will help ensure that the engine is properly maintained and prevent potential issues down the road.

Following these tips can help prevent potential issues with your Exmark Kohler engine and ensure proper engine performance.

Frequently Asked Questions (FAQs)

Can I drive my Exmark Kohler engine with a blown head gasket?

It’s not recommended to drive your engine with a blown head gasket because it can cause further damage and lead to heavy repairs.

How do I know if my Exmark Kohler engine has a blown head gasket?

If you notice any coolant leakage, power issues, or poor engine performance, your engine may have a blown head gasket.

A professional mechanic can perform pressure tests or other inspections to confirm whether your gasket needs attention.

Conclusion

To sum up, Exmark Kohler engines are reliable and effective machines that require routine maintenance to ensure their long lifespan and peak performance.

However, problems such as oil leaks and blown head gaskets may arise even with proper care.

It is essential for owners to be aware of the signs of these issues and to take measures to avoid them.

If any problem arises, it is important to identify and fix it immediately to prevent further damage to the engine.

While the owner can handle minor repairs, seeking professional help for more complex issues, such as blown head gaskets and major engine repairs, is recommended.

By following proper maintenance procedures and addressing issues timely, owners can ensure that their Exmark Kohler engine continues to function at its best and provides long-lasting service.